Resinous Flooring is utilized in a variety of commercial and industrial facilities to enhance the performance and durability of concrete floors and increase the overall lifecycle value of a plant.

Depending upon your facility needs, CDC LC can customize your floor coating system to withstand specific chemical exposures, abrasion, or sanitation requirements.

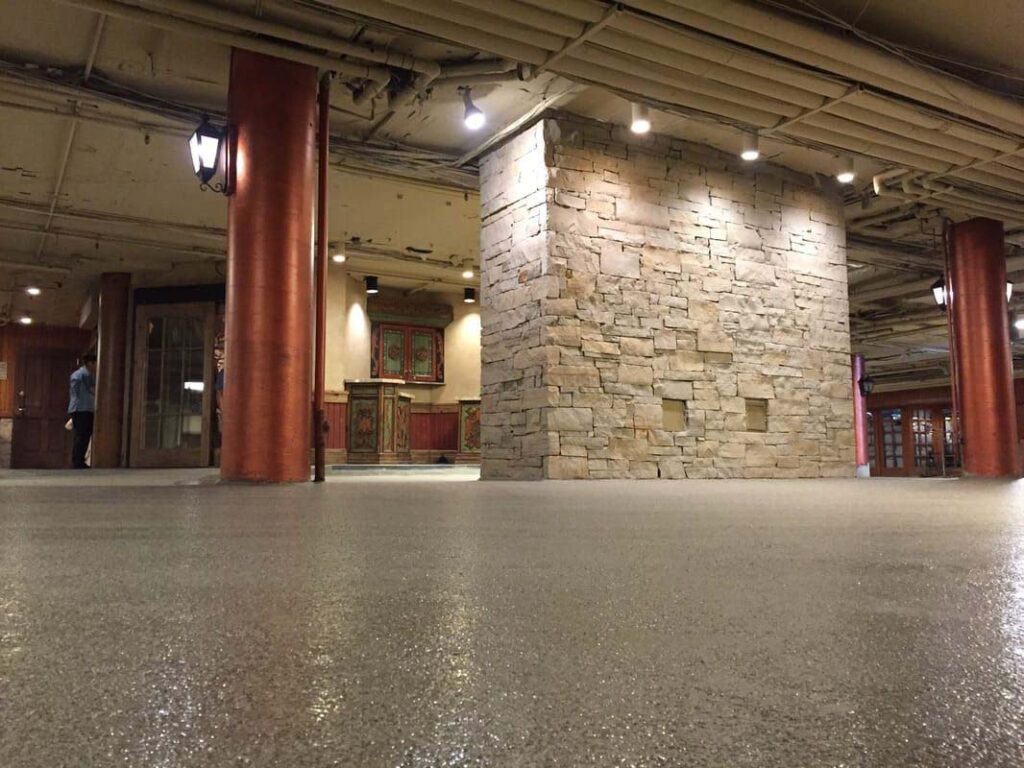

Floor Coatings help to improve plant aesthetics and provide a safer work environment for employees by increasing light reflection, enhancing visibility in production areas, and providing a more easily cleaned walking surface. A brighter, cleaner atmosphere also helps to stimulate productivity in employees and impresses potential customers when visiting your facility.

Benefits of Resinous Flooring

- Enhances Visibility in Work Areas

- Decreases Facility Lighting Costs

- Increases Worker Productivity

- Creates a Safer Environment

- Improve Plant Aesthetics

- Enhanced Sanitation

- Chemical Protection

- Abrasion and Impact Protection

Chemical Resistant Floor Systems

Epoxies, Novolacs, Vinyl Esters, Polyesters, and Polyurethanes, to name a few, can all be utilized to provide varying levels of chemical resistance based on your requirements. These systems can also utilize special fillers such as glass flakes to increase chemical resistance.

Heavy Duty Floor Systems

Heavy Duty Systems are an excellent choice for the economical repair of moderate to severely deteriorated concrete floors. They provide sanitary, skid-resistant, and highly impact-resistant surfaces. They exhibit high compressive strength and point-load capacities.

Seamless Flooring

Eliminating joints and cracks in the floor surface improves sanitation by reducing areas where dirt and debris can collect. Eliminating joints reduces wear and tear on forklifts and other equipment. For Food Processing environments, joints and cracks provide a safe haven for bacterial growth.